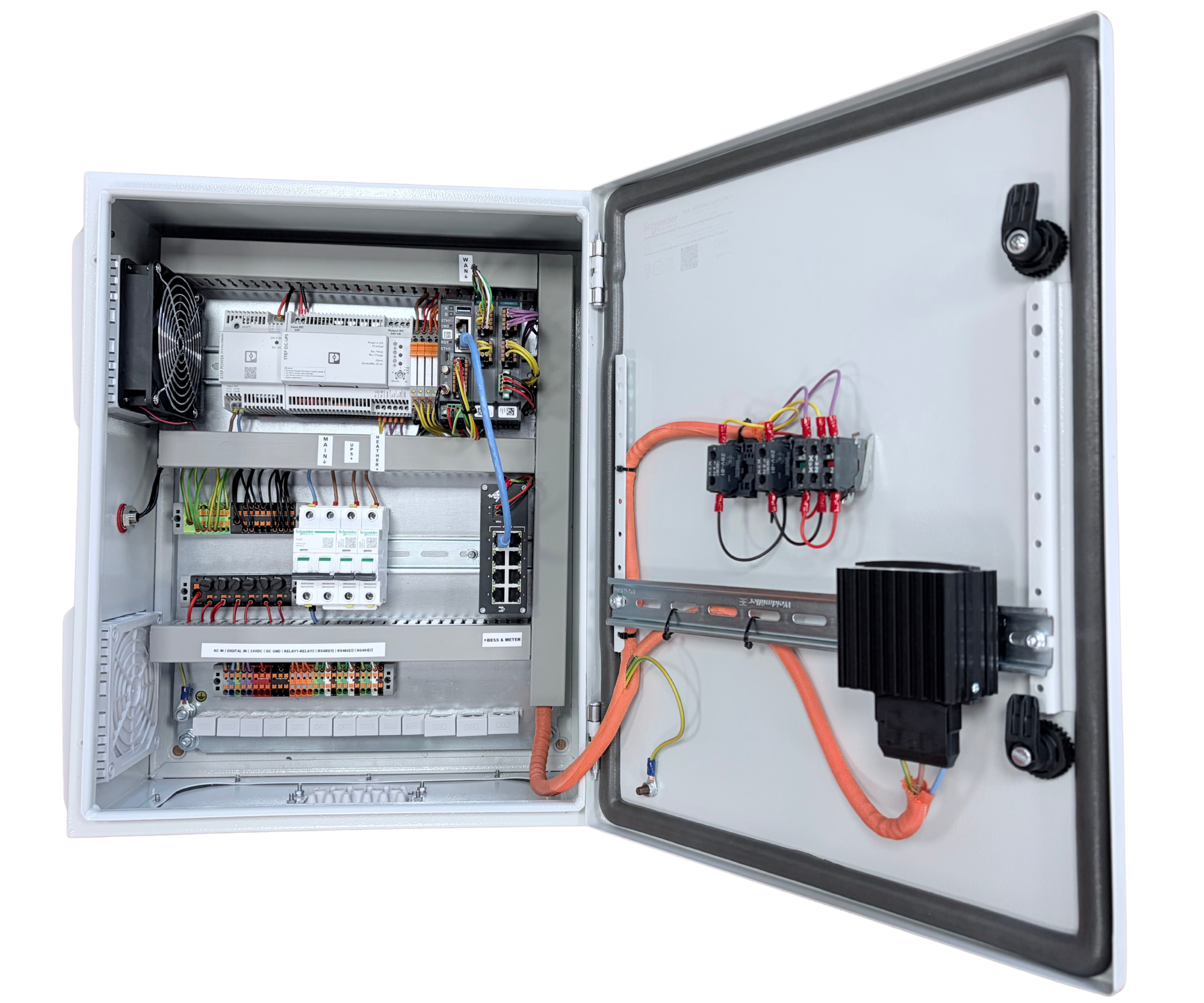

Control cabinet - L

Local control functions

-

One disadvantage of solar power systems equipped with back-up protection is that they can only generate energy for immediate consumption. If there is no immediate use, the system regulates itself, resulting in production fluctuations and lower efficiency. As a result, the self-consumption ratio also remains low.

The control solution we offer is capable of directing the solar energy generated into the battery, taking local conditions into account. This allows the system to operate continuously and in a balanced manner, while significantly increasing the rate of self-consumption and utilizing renewable energy sources much more efficiently.

-

In certain industrial systems, it is a fundamental requirement that neither the energy generated by solar panels nor that stored in batteries be fed back into the public grid. The EMS control unit continuously monitors the operation of the entire system and dynamically regulates the equipment based on data from the energy meters. As a result, the energy generated is used for local consumption under all circumstances, while feeding back into the grid is completely prevented.

-

This feature offers a significant advantage where available grid capacity is insufficient or where it would be uneconomical to pay higher fees due to short-term power peaks. By incorporating energy storage, the system is able to balance the load, ensuring continuous and stable operation while avoiding costly grid expansion. A good example of this is the support of electric vehicle charging stations: the storage system dynamically assists charging when the network capacity alone is insufficient, ensuring that charging remains reliable and continuous without having to tie up unnecessary additional capacity.

-

In the case of spot price energy contracts, it is particularly important to consciously manage intraday price fluctuations. Every day, our energy management system automatically queries the next day's electricity prices on the exchange, identifies off-peak and peak periods, and then creates a schedule based on this information. Accordingly, the system charges the battery from the grid during cheaper hours, so that internal consumption during more expensive peak periods can be covered by stored energy. This results in significant cost savings without having to change consumption habits.

-

Our system is capable of receiving control signals from aggregators via the most common industrial communication protocols and executing them locally in real time. It effectively supports not only energy storage devices, but also gas engines and solar power plants. In addition to external commands, the built-in local control continuously monitors critical requirements such as protection against backfeed or compliance with network capacity limits. This ensures that external and local control always work in a coordinated and safe manner.

-

Equipment connected to the control cabinet can be flexibly controlled using digital inputs, outputs, and relays. Automated control of various consumers or technological elements can be implemented based on unique logic. For example, in the event of excess solar energy, the hot water production system or a cooling compressor can be automatically switched on. Another practical example is when it is necessary to disconnect or automatically reconnect a motor circuit breaker or read its current status.

Technical Specifications

| General information | |

|---|---|

| Nominal AC voltage | 230 Vac / 0.5 A |

| Connections | 1 WAN RJ45 port 7 LAN RJ45 ports for controlled devices (intranet switch) 3 terminal block RS-485 ports 2 terminal block inputs 2 terminal block relay outputs 1 terminal block AC power supply |

| Uninterruptible power supply (UPS) | yes (~ 3 hours) |

| 4G LTE data connection | yes |

| Internal data connection for controlled devices | Modbus TCP/IP, Modbus RTU |

| External data connection for remote control | MQTT, REST API, Modbus TCP/IP |

| Controls and feedback | LED indicators: system operating status, controller operating status, fault status Remote monitoring: Remote adjustment of operating parameters, viewing of operating data |

| Dimensions and weight | 500 x 400 x 200 mm, ~15 kg |

| IP protection and material | IP54, Steel plate, RAL 7035 |

| Operating temperature | -25 to 45 °C (active ventilation, cabinet heating) |

| Accommodation | Indoors or outdoors, wall-mounted (mounting brackets included) |

| Warranty | 5-year warranty |

| Certificates | The control cabinet has a CE declaration of conformity (EN 61439-1/2, EN 60529, HD 60364-4-41, EN 61140), the built-in components have CE and appropriate certifications and have been integrated in accordance with the manufacturers' specifications. |

Control Cabinet - L Hardware Functions

Compact design, robust construction - Designed for industrial use

The outdoor control cabinet contains all the necessary components in a single, compact design: industrial control unit, 4G modem, switch, control elements, digital I/O and relay outputs, and an uninterruptible power supply. To ensure reliable operation, the cabinet is equipped with active fan cooling and heating to prevent internal condensation. Thanks to the external mounting lugs, it can be quickly and easily installed directly in the environment of the controlled system.

4G data connection and external antenna

The 4G modem integrated into the control unit ensures access to the device even where no wired Internet connection is available. Thanks to its special switchover function, it automatically switches to mobile internet within 15 seconds in the event of a network failure, then switches back to the primary source once the main network (Ethernet WAN) is restored.

Intranet switch

The control cabinet has two separate Ethernet networks, which provide secure and flexible network connectivity. One Ethernet interface is used for external data connections, such as remote monitoring, data transmission, and cloud services.

In contrast, the switch connected to the intranet Ethernet interface offers a completely separate, protected internal network. When controlled devices are connected to this switch, they do not have Internet access, thus enabling a higher level of security. This is particularly advantageous in environments where network policies strictly restrict Internet access for devices connected to the internal network.

The separation of the two networks ensures that local control operates securely and without disruption, while maintaining flexibility to provide Internet access as needed.

Stop button, indicator LEDs

The stop button on the control cabinet door can be used to switch off the storage or solar system and the automatic operation software, and then restart them if necessary. The built-in indicator LEDs provide immediate status information: the white LED indicates continuous operation of the control system, while the red LED lights up when a fault occurs in any of the monitored devices. This solution provides operators with quick and clear information about the operation of the system.

Digital IO, relay outputs

The cabinet's digital inputs and relay outputs enable direct control of various devices and feedback on their status. The interfaces, which operate at a signal level of 24 V, ensure simple and reliable integration with industrial consumers, control cabinets, or safety elements. This allows the system to be flexibly adapted to local requirements, whether for switching tasks, start/stop functions, or receiving status signals.

Uninterruptible power supply (UPS)

In the event of a power failure, the system switches over to the battery power source located in the control cabinet without interruption. This allows the control unit to continue operating, so that the monitoring system can provide accurate error messages about the cause of the power supply problem, eliminating unnecessary false alarms, such as those caused by storage or control system errors. The backup time provided by the uninterruptible power supply is typically 3 hours.

Unlike classic lead-acid solutions, the uninterruptible system built into our control cabinet operates with a Li-ion battery, which offers a significantly longer service life. This eliminates the need for on-site battery replacement every 1-2 years, minimizing maintenance requirements while ensuring long-term operational reliability.